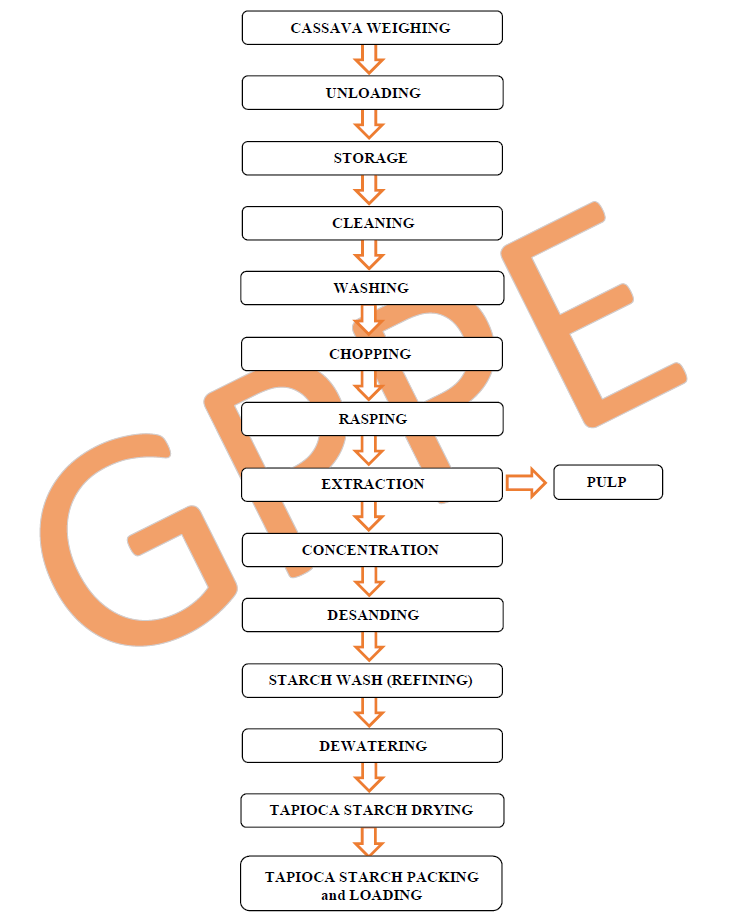

Cassava / Tapioca Starch

Cassava is weighed and unloaded. Soil, sand, gravel, stones and all kind of impurities are removed in cleaning and washing section. It is critical to eliminite all kind of dirt and foreign material from roots as they affect final starch product quality. Washed roots are fed to pre cutter equipment which increase efficiency of the rasper. Tapioca starch process is identical to potato starch process and same equipments are used except precutter. In potato starch process potatoes are fed directly to rasper after washing but in Cassava process there is also precutter (also called Chopper) Thanks to Rasper Starch granules are released in pulpy slurry. Following to Rasper mixture is fed to magnetic filter and then Rotating Conical Screens. Pulp is separated and washed in rotating conical screens and dewatered.

Dewatered Pulp has 10-15% dry substance and can be used as cattle feed or biogas production. Rotating Conical screen separation and washing section is named as Extraction. Following extraction, main stream is fed to Concentration section. In concentration section density of starch fraction is increased and fruit juice is separated. It is critical to have minimum impurities in starch friction and minimum starch loss with juice. Concentrated starch friction is fed to desanding unit in order to eliminate any remaining high density foreign material from starch. Following desanding unit, starch is washed countercurrently in multiple stages hydrocyclone unit with fresh water in order to separate any remaining fruit juice, fiber etc… Refined starch is fed to dewatering section (Peeler Centrifuge or Rotary Vacuum Filter) and starch cake from dewatering equipment is fed to dryer to meet final product moisture content specification.

EN

EN

TR

TR